Depends on different materials and the marking effects you want so for a new operator may need conduct dozens of trials to know the ideal marking parameters for each material and even some experienced engineers.

Laser marking process parameters.

What materials can be marked with a laser.

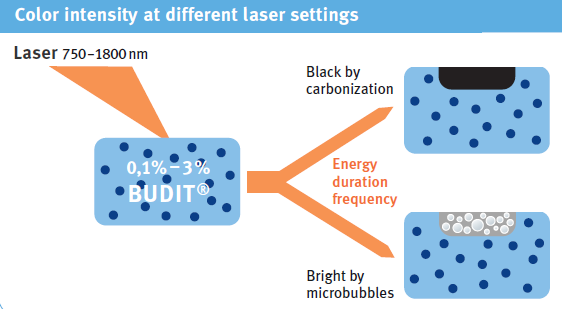

Altering this frequency creates different marking effects.

This results in high productivity and cost benefits during manufacture.

The q switch is an electro optical system which controls the opacity of a lens making it possible to change the laser beam frequency.

The investigations were performed using a commercially available industrial pulsed fiber laser.

For objective assessment of color changes a cie color difference formula delta e ab was.

Plastics which as a result of a laser marking process show no contrast in the pre doping phase display a legible inscription after the additive has been added.

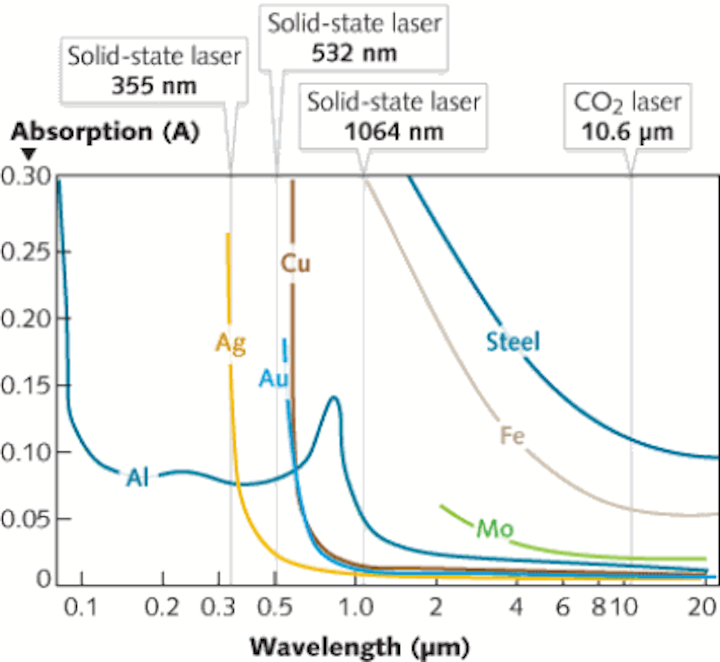

In this work laser surface marking was performed on titanium substrate using doubled frequency pulsed nd.

This parameter is used to adjust the laser output frequency by directly operating the q switch.

Yes there are a number of proven examples of laser marking transparent bottles in the beverage industry.

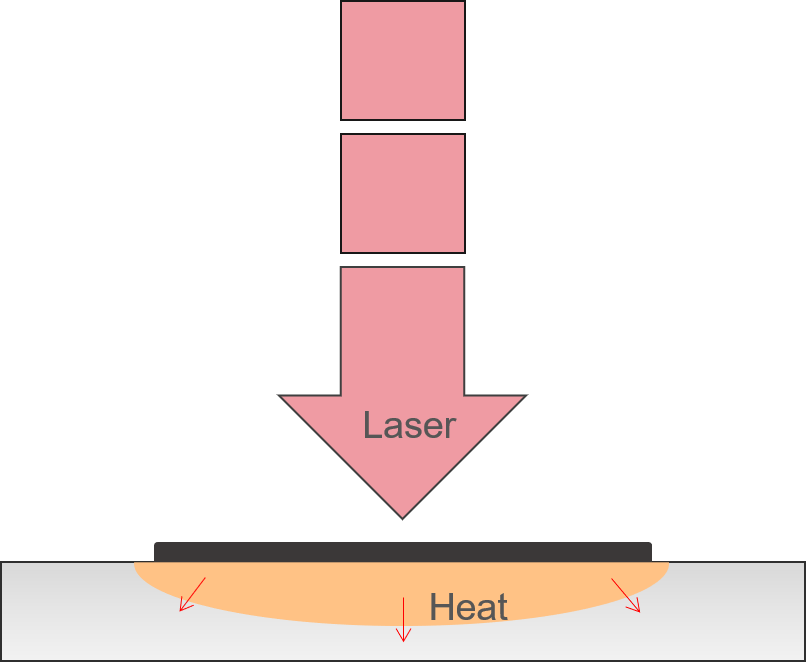

Depending on the laser parameter settings certain materials can also be marked without damaging the surface.

An additive is mixed into gabocom s pe pipes in order to ensure that the laser marking process generates high contrasts.

In marking metal and plastic there is a setting parameter range for reference to test speed 100 2000 adjustable power 30 80 adjustable frequency 5 30.

During the carbonizing process the.

The color of marking is different than a mark produced by an inkjet printer.

Pulse 5 ns to process the surface under normal atmospheric.

Laser etching process is used for marking those materials which cannot be marked by conventional machining processes.

This is an application that is often used to print the time of manufacturing and the expiration date on the product.

Yag green laser 532 nm.